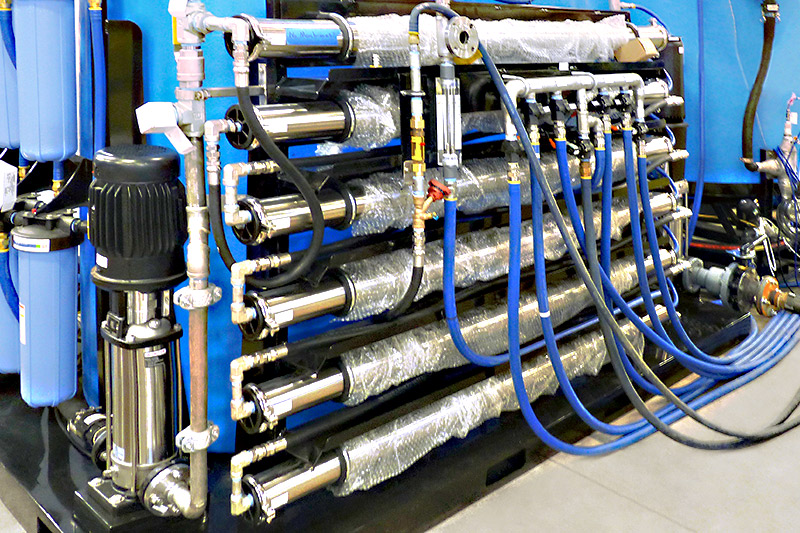

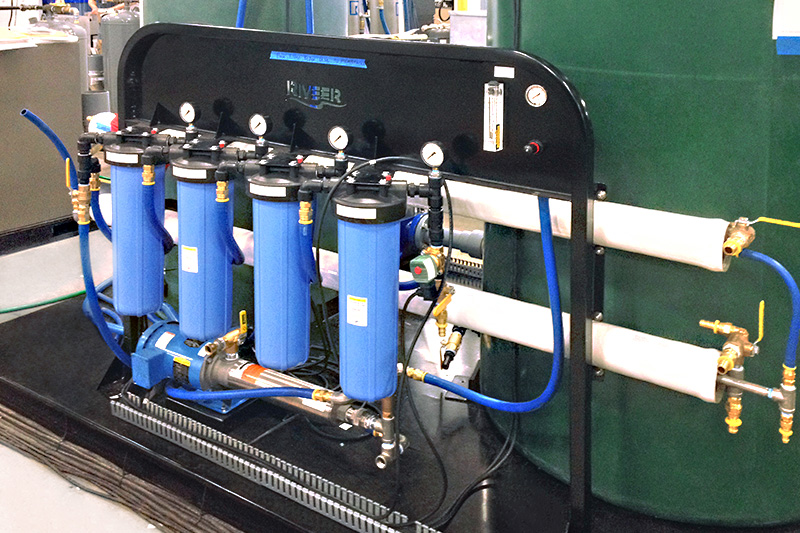

Turbine engines require periodic washing and flushing to maintain performance. All of the turbine manufacturers require exceptionally clean water, better than potable or tap water, to prevent deposits from being formed. Turbine flush water may not have dissolved solids (hardness) that is commonly found in nearly all tap water. Rinse water must be either DI (deionized) or RO (reverse osmosis) water with TDS levels that are near zero. Creating ultrapure water for Turbine Engine Flush operations using Riveer packaged water pre-treatment systems is simple, reliable, and critically traceable.

Whether your tap water is high in turbidity, scale, hardness, chlorine, chlorides, or unknown contaminants, the Riveer packaged water systems should be used to ensure ultra-pure water is being used in your high cost, high performance, and highly precision turbine engine. Use the proper water quality in your engine cleaning operations every time by installing a stand-alone Riveer RO and DI system. The holding tank will maintain flush ready water for your flight line maintenance needs.